The Complete Guide To Slot Weld Symbols: Mastering The Basics And Beyond

What is a Slot Weld Symbol?

A slot weld symbol is an industry-standard way to indicate the location and type of slot weld. Weld symbols are used on engineering drawings to convey the designer's intent and provide instructions to the welder.

Slot welds are typically used to join two pieces of sheet metal. The weld is made by passing a welding electrode through a slot in one of the pieces of metal. The electrode is then melted and fused to the other piece of metal. Slot welds are often used in automotive and aerospace applications.

The slot weld symbol consists of a circle with a line through it. The circle represents the location of the weld, and the line represents the slot. The size of the circle indicates the diameter of the weld, and the length of the line indicates the length of the slot.

Slot weld symbols can also include other information, such as the type of weld, the welding process, and the welding parameters. This information is typically included in a note next to the weld symbol.

A slot weld symbol is a crucial element in technical drawings, providing essential information for the fabrication of metal structures. It encompasses various aspects related to the weld's characteristics and application.

- Location: Specifies the precise position of the weld.

- Type: Indicates the specific type of slot weld, such as continuous or intermittent.

- Size: Defines the dimensions of the weld, including its length and width.

- Process: Identifies the welding process to be employed, such as MIG or TIG welding.

- Parameters: Provides details about the welding parameters, such as current and voltage.

- Orientation: Indicates the direction of the weld relative to the workpiece.

These key aspects of slot weld symbols ensure clear communication between designers and fabricators. They enable accurate interpretation of engineering drawings, leading to precise execution of welding operations. Proper understanding and application of slot weld symbols are vital for the integrity and reliability of welded structures across diverse industries.

Location

Within the context of slot weld symbols, specifying the precise location of the weld is of paramount importance as it directly influences the structural integrity and functionality of the welded joint. The location of the weld determines the load-bearing capacity, stress distribution, and overall performance of the assembly.

For instance, in automotive manufacturing, precise weld placement ensures proper alignment of body panels, doors, and other components. Accurate weld location minimizes distortion, reduces the risk of weld failure, and contributes to the vehicle's overall safety and aesthetics.

Furthermore, in the construction industry, precise weld location is crucial for structural stability. In bridges, buildings, and other large-scale structures, welds must be placed at specific locations to withstand the anticipated loads and stresses. Proper weld placement ensures load transfer, prevents premature failure, and contributes to the longevity and reliability of the structure.

In summary, understanding the connection between "Location: Specifies the precise position of the weld" and "slot weld symbol" is essential for accurate weld execution and ensuring the integrity and performance of welded structures across various industries.

Type

In the realm of welding, "Type" plays a pivotal role in the "slot weld symbol," conveying the specific type of slot weld to be employed. Understanding the different types of slot welds is essential for achieving the desired weld characteristics and ensuring the integrity of the welded joint.

- Continuous Slot Welds

Continuous slot welds involve a continuous weld along the entire length of the slot. They provide a strong and durable joint, ideal for applications requiring high load-bearing capacity. Automotive frames, pressure vessels, and structural components often utilize continuous slot welds for their robust nature.

- Intermittent Slot Welds

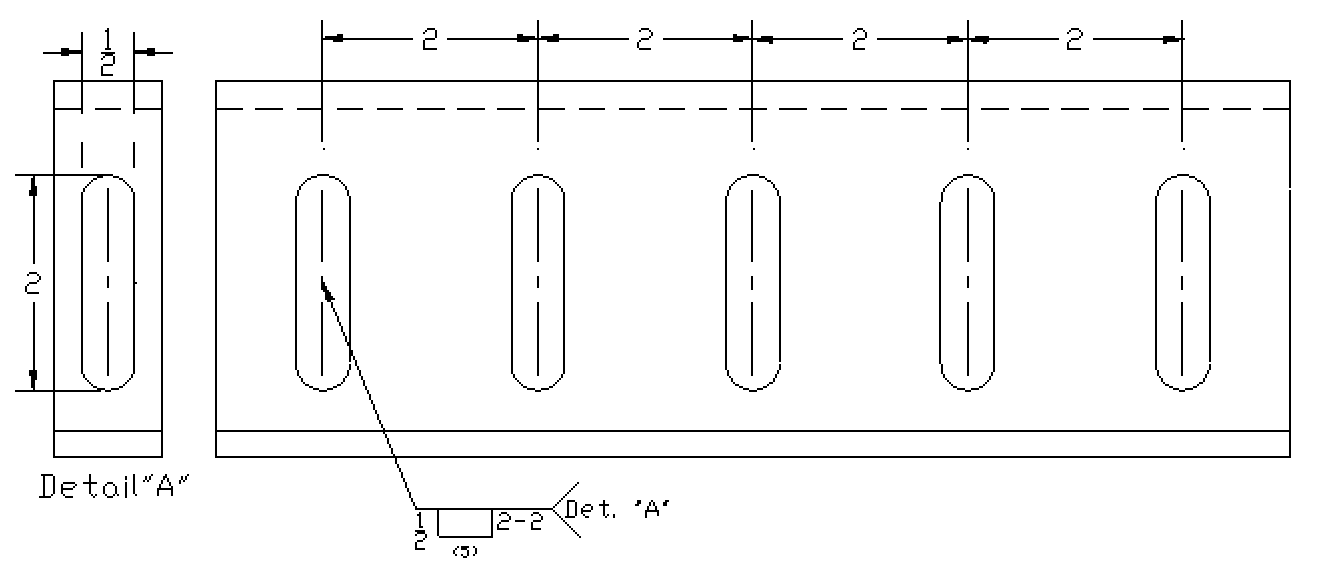

Intermittent slot welds, on the other hand, consist of a series of evenly spaced welds along the length of the slot. This type of weld offers flexibility and is suitable for applications where continuous welding may cause excessive heat buildup or distortion. Intermittent slot welds are commonly found in sheet metal fabrication, electronic enclosures, and assemblies requiring precise alignment.

Selecting the appropriate type of slot weld is crucial for optimizing joint performance. Continuous slot welds provide maximum strength and rigidity, while intermittent slot welds offer a balance between strength and flexibility. Understanding the implications of each type ensures the proper execution of welding operations and the attainment of desired weld characteristics.

Size

Within the context of slot weld symbols, "Size" holds significant importance as it dictates the dimensions of the weld, encompassing its length and width. Understanding the implications of size is paramount for achieving optimal weld performance and ensuring structural integrity.

The length of the slot weld directly influences the load-bearing capacity and strength of the joint. Longer welds distribute stress more effectively, resulting in a more robust connection. In applications such as automotive frames and heavy machinery, longer slot welds are employed to withstand substantial loads and vibrations.

The width of the slot weld, on the other hand, impacts the penetration and fusion of the weld. Wider welds provide deeper penetration, leading to a stronger bond between the joined materials. Industries like shipbuilding and pressure vessel fabrication rely on wide slot welds to ensure leak-proof and pressure-resistant joints.

Specifying the correct size in a slot weld symbol is essential for optimizing weld performance. By considering factors such as load requirements, material thickness, and desired strength, engineers can determine the appropriate dimensions for the weld. Proper sizing ensures efficient load transfer, minimizes stress concentrations, and enhances the overall reliability of the welded structure.

Process

Within the realm of welding, selecting the appropriate welding process is crucial for achieving the desired weld characteristics and ensuring the integrity of the joint. In the context of slot weld symbols, the "Process" component plays a vital role in conveying the specific welding process to be employed, such as MIG or TIG welding.

- MIG Welding (Metal Inert Gas)

MIG welding, also known as GMAW (Gas Metal Arc Welding), is a widely used process for slot welding. It involves feeding a continuously fed wire electrode into the weld zone, while an inert gas (such as argon or helium) shields the weld from contamination. MIG welding offers high deposition rates, making it suitable for long and continuous slot welds. It is commonly employed in automotive manufacturing, shipbuilding, and general fabrication.

- TIG Welding (Tungsten Inert Gas)

TIG welding, also known as GTAW (Gas Tungsten Arc Welding), is another prevalent process for slot welding. It utilizes a non-consumable tungsten electrode to generate an arc between the electrode and the workpiece. The weld zone is shielded by an inert gas, typically argon. TIG welding provides precise control over the weld pool and allows for high-quality welds with minimal spatter. It is often used in aerospace, medical device manufacturing, and other applications requiring precision and cleanliness.

Understanding the implications of each welding process is essential for selecting the most suitable method for a given application. Factors such as material thickness, joint geometry, and desired weld properties influence the choice of process. By specifying the welding process in the slot weld symbol, engineers can ensure that the welder uses the appropriate technique to achieve optimal weld quality and performance.

Parameters

Within the context of slot weld symbols, "Parameters" play a critical role in conveying essential information about the welding conditions necessary to achieve optimal weld quality. These parameters, such as current and voltage, directly influence the characteristics of the weld, including its penetration, bead shape, and strength.

- Current

Welding current, measured in amperes (A), determines the amount of heat input into the weld zone. Higher currents result in deeper penetration and wider welds, while lower currents produce shallower penetration and narrower welds. Selecting the appropriate current is crucial for achieving the desired weld properties, such as strength and ductility.

- Voltage

Welding voltage, measured in volts (V), affects the arc characteristics and weld bead profile. Higher voltages create a longer arc, resulting in a more focused and concentrated heat input. This can lead to deeper penetration and narrower welds. Conversely, lower voltages produce a shorter arc, resulting in a wider and shallower weld bead.

Other welding parameters that may be specified in a slot weld symbol include travel speed, shielding gas type and flow rate, and electrode diameter. By providing detailed information about these parameters, the slot weld symbol ensures that the welder has all the necessary information to execute the weld according to the designer's intent. Proper adherence to the specified parameters helps to maintain consistent weld quality, minimize defects, and enhance the overall performance and reliability of the welded joint.

Orientation

In the realm of welding, orientation plays a pivotal role in determining the direction of the weld relative to the workpiece. This aspect is meticulously captured within the "slot weld symbol," conveying crucial information for precise weld execution.

- Weld Direction

Weld orientation primarily defines the direction in which the weld is to be executed. It can be specified as horizontal, vertical, or at an angle. Understanding the weld direction is critical for proper joint preparation, electrode selection, and ensuring optimal weld penetration.

- Workpiece Alignment

Weld orientation also dictates the alignment of the workpiece during the welding process. Whether the workpiece is positioned flat, vertical, or overhead significantly impacts the welder's accessibility, the weld pool's behavior, and the overall weld quality.

- Joint Design

The orientation of the weld directly influences the joint design. Different joint configurations, such as edge-to-edge, T-joints, or corner joints, require specific weld orientations to achieve proper fusion and strength.

- Weld Accessibility

Weld orientation also considers the accessibility of the weld joint. Ensuring proper access for the welding equipment and the welder is essential for efficient and safe welding operations.

By incorporating orientation information into the slot weld symbol, engineers and fabricators can ensure that the weld is executed precisely as per the design intent. Accurate weld orientation contributes to structural integrity, weld strength, and the overall performance of the welded component.

FAQs

This section addresses frequently asked questions regarding slot weld symbols, providing informative answers to clarify their significance and application.

Question 1: What is the purpose of a slot weld symbol?

A slot weld symbol is a standardized graphical representation that conveys essential information about a specific type of weld. It indicates the weld's location, type, size, process, parameters, and orientation, ensuring clear communication between designers and fabricators.

Question 2: How does a slot weld symbol specify the weld's location?

The location of the weld is indicated by a circle or a combination of circles and lines within the slot weld symbol. The size and position of these elements precisely define where the weld is to be placed on the workpiece.

Question 3: What are the different types of slot welds, and how are they represented in the symbol?

Slot welds can be continuous or intermittent. Continuous slot welds are represented by a solid line within the circle, while intermittent slot welds are represented by a series of evenly spaced dashes.

Question 4: How does the size of the slot weld symbol relate to the actual weld dimensions?

The size of the circle or circles within the slot weld symbol represents the diameter of the weld. The length of the lines or dashes indicates the length of the weld.

Question 5: What information is conveyed by the welding process and parameters in the slot weld symbol?

The welding process is indicated by a letter or combination of letters within the symbol. The welding parameters, such as current and voltage, may also be specified to ensure that the weld is executed according to the designer's intent.

Question 6: How does the orientation of the slot weld symbol impact the weld execution?

The orientation of the slot weld symbol indicates the direction of the weld relative to the workpiece. This information is crucial for proper joint preparation, electrode selection, and achieving the desired weld quality.

By understanding the slot weld symbol's components and their significance, engineers, fabricators, and inspectors can ensure accurate and consistent weld execution, leading to reliable and high-quality welded structures.

Transition to the next article section: This comprehensive overview of slot weld symbols provides a solid foundation for further exploration of welding techniques, joint designs, and quality control measures.

Tips for Utilizing Slot Weld Symbols Effectively

Slot weld symbols are a crucial aspect of welding documentation, and their accurate interpretation and application are essential for successful welding operations. Here are some tips to help you effectively utilize slot weld symbols:

Tip 1: Understand the Basic Components

Familiarize yourself with the different components of a slot weld symbol, including the reference line, arrow, circles, and other elements. Each component conveys specific information about the weld's location, type, size, and other parameters.

Tip 2: Pay Attention to Detail

Accurately interpret the dimensions and specifications provided in the slot weld symbol. Even minor deviations from the specified values can impact the weld's quality and performance.

Tip 3: Consider the Welding Process

The welding process specified in the slot weld symbol influences the equipment and techniques used. Ensure that the appropriate welding process is selected based on the material properties, joint design, and desired weld characteristics.

Tip 4: Verify Weld Parameters

Welding parameters such as current, voltage, and travel speed can significantly affect the weld's quality. Verify that the specified parameters align with the recommended values for the chosen welding process and materials.

Tip 5: Ensure Proper Orientation

The orientation of the slot weld symbol indicates the direction of the weld relative to the workpiece. Ensure that the weld is executed in the correct orientation to achieve proper fusion and joint integrity.

Tip 6: Use Clear Communication

When conveying slot weld symbol information, use clear and concise language. Avoid ambiguities or assumptions that could lead to errors in interpretation.

Tip 7: Reference Standards

Adhere to established standards and codes when interpreting and applying slot weld symbols. This ensures consistency and accuracy in welding practices.

Summary: By following these tips, engineers, fabricators, and inspectors can effectively utilize slot weld symbols to ensure precise and reliable welding operations. Accurate interpretation and application of slot weld symbols contribute to the structural integrity, performance, and safety of welded components.

Conclusion

The slot weld symbol is a powerful tool for communicating complex welding information in a concise and standardized manner. By understanding the components, interpretation, and application of slot weld symbols, engineers, fabricators, and inspectors can ensure accurate and reliable welding operations.

Proper utilization of slot weld symbols contributes to the structural integrity, performance, and safety of welded components. It facilitates effective communication between designers, fabricators, and inspectors, minimizing errors and ensuring that welds meet the intended design specifications.

Unleash The Thrills: Discover The World Of Slot Cars

The Ultimate Slot 2 Pendant Guide For Any Occasion

Discover The Thrill Of Net77 Slot: Your Gateway To Excitement